HOLLOW SECTIONS

Hollow sections or pipes are manufactured on a tube mill using high frequency induction welding technique. The flat strip is seam welded while round in shape and then gradually brought to the desired section in the sizing mill. The welded seam is put to a great amount of cold working while being sized. This is a very severe test of the strength of a seam weld and ensures that each length of hollow section is welded for maximum strength.

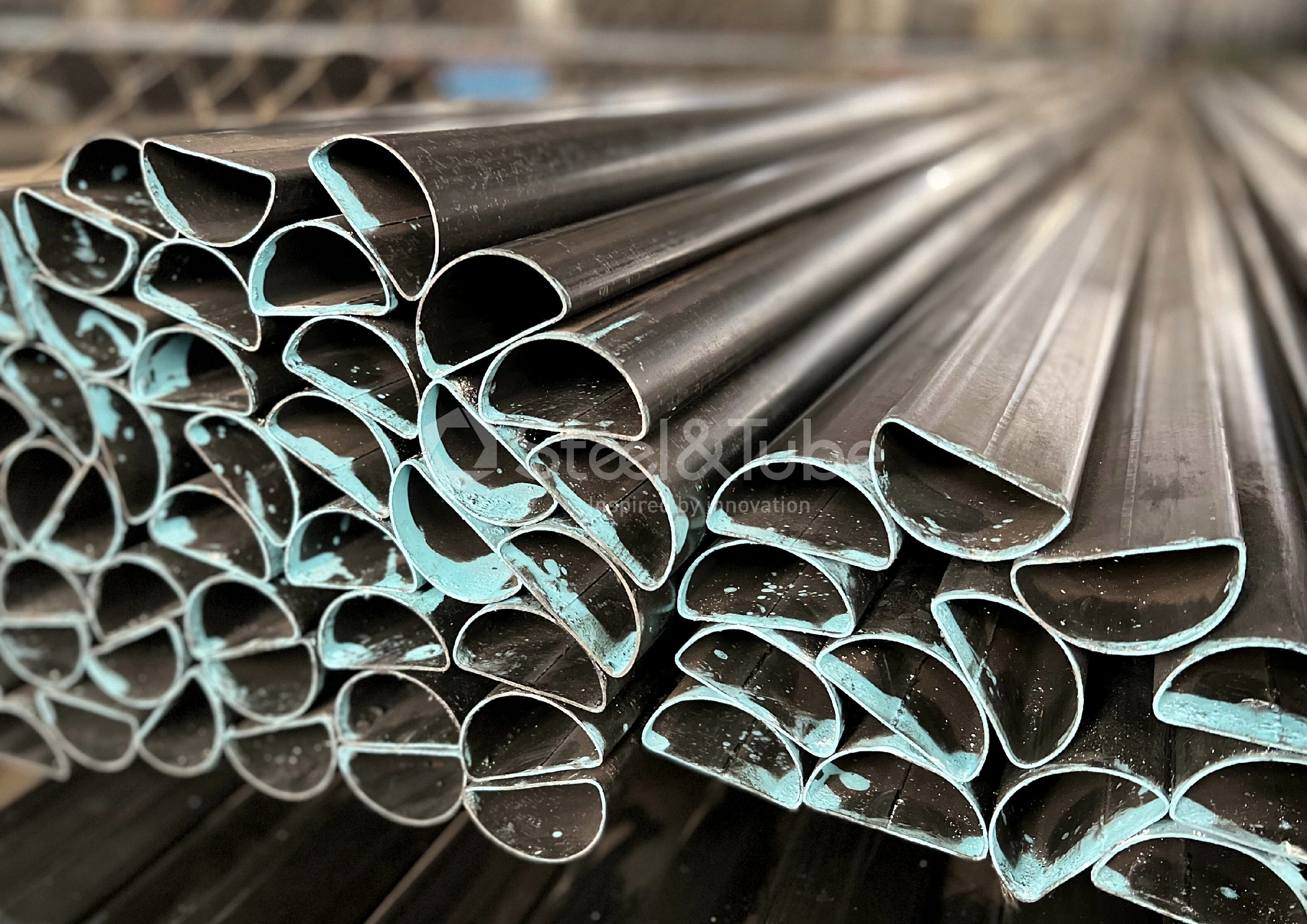

The pipes are produced in Round, Rectangular, Square and D-pipe sections conforming to high leading international standards: US EAS 134, JIS G3132.

OPEN PROFILES

Open profiles are cold formed using hot rolled steel strips. During rolling, care is taken to ensure perfect dimensional uniformity, extremely smooth surface finish and accurately finished edges.

Open profiles are used in many modern buildings; from apartments to educational institutions, low cost housing to high rise complexes.

SECTIONAL PROPERTIES OF OPEN PROFILES

- Highest possible resistance to torsion.

- Their low flat – width ratio (w/t) permits higher design stresses.

- Comparably higher moment of inertia about minor axis prevents premature elastic bucking.

- Due to availability of flat surface, joining by bolting or welding is simplified.

- Due to high moment of inertia deflections are lower.

- Consistency in quality.

- Smooth contact and low drag coefficient minimizes wind load on exposed surface.

- Availability in exact length reduces wastage of steel.

- High strength to mass ratio

- Better fire resistance due to larger heat dissipating area and lower heat absorbing area

- Sealed end prevents internal corrosion.

SAVING

- Ease of erection and adaptability for prefabricated panels reduces construction time.

- Due to light weight, cost of other supporting members, foundations, handling and transportation is reduced.

- Smaller exposed surface area reduces cost of painting and susceptibility to corrosion. Direct welding to each other avoids the need for gusset plates which saves 2-3% cost in steel and sledding electrodes.